Since 1948, Bopp Busch has believed in being more than a supplier. We believe in being a partner supplier. We approach every customer relationship to not only provide exceptional stamping services, but to help you to succeed. In the past seven decades, Bopp Busch Manufacturing Company has grown from an original facility of less than 10,000 sq ft to a manufacturing area of 128,000 square foot ft in four locations. Serving over nearly 300 manufacturing companies in its history, Bopp Busch carries on its tradition of exceptional, service, quality and value. We are proud of our heritage of meeting customer requirements and the growth we have experienced. To serve those customers better, we expanded our services over the years. Our partner supplier services include:

Tool & Die Making

Stamping

Welding

E-coat Paint

General Assembly

Product Engineering

The support services we offer delivers a quicker beginning to end process for your product. From welding to e-coating to assembly, the more finished you receive your part, the better your bottom line. As your partner supplier, the quality of the parts we manufacture meet industry-leading performance standards consistently. This fact is proven by our low PPM rating and high on-time delivery percentage.

The support services we offer delivers a quicker beginning to end process for your product. From welding to e-coating to assembly, the more finished you receive your part, the better your bottom line. As your partner supplier, the quality of the parts we manufacture meet industry-leading performance standards consistently. This fact is proven by our low PPM rating and high on-time delivery percentage.

As the maxim goes, “attitude is everything.” A partner stamping supplier, the Bopp Busch team does what it takes to get you through an emergency or provide advice to help lower costs or production times. Because we foster that attitude, we have built many mutually-beneficial and long-term relationships. As a partner supplier, we meet specifications, deadlines, and quality seamlessly. Bopp Busch focuses on being a manufacturing partner supplier to a variety of industries including: Aerospace, Automotive, Defense, Lawn & Garden, Medical, Recreational Vehicle, Agricultural Equipment, Construction Equipment, and Food Products & Chemical Processing Equipment.

We serve customer with stamping services and more from throughout the northern and southern Midwest. Contact us for a quote on your project.

When we work with a customer, we are committed to help with the challenges you face, such as cost savings initiatives. As a stamping partner supplier, we have a long history of sharing cost reductions with our customers. Continual improvement of production throughput is part of our commitment as your stamping partner supplier. We invest in robotics, new equipment and technology upgrades to deliver the most cost efficient production possible. Knowing you have a stamping supplier you can rely on is essential to your operations. Bopp Busch has a seven decade track record of financial strength and stability.

Poor quality parts can mean downtime and production delays. Bopp Busch operates under TS-16949 Quality System and maintains a world class low PPM rating. This assures you of the highest quality standards for all products Bopp-Busch supplies. A disruption to your supply chain can have far reaching negative impacts. As your stamping partner supplier, we are responsive to your supply demands, In fact, we have never been the cause of an assembly line shut down and have 99.9% on time delivery rate. Cold welds can cause major assembly disruptions. Our in-house welding expertise delivers high quality welds with a low defect rate ahead of our competition.

With our in-house die shop and rapid die building capabilities we can meet the challenge of late release and urgently needed parts. At Bopp-Busch, our greatest strength lies within our committed employees. Our non-union workforce provides dependable, responsive service. Promising quality and delivery are only good if you stand behind them. As a proven stamping partner supplier, we offer our On-time Delivery and Quality Guarantees to assure your parts will arrive on time and to your specifications.

Responsibility, quality, and reliability are the standards that guide our stamping manufacturing. Contact Us

Over the decades, Bopp Busch has expanded our serves to be a comprehensive stamping supplier. Our full services include:

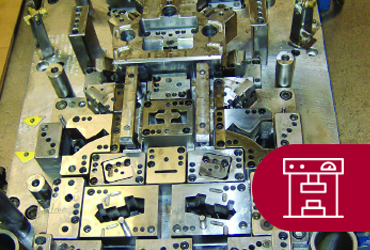

Our tool and die building expertise includes progressive dies, line dies, weld fixtures and attribute checking fixtures.

We stamp small to medium sized parts of .5 mm to 5 mm thickness. Whether you need low or high volume production runs, you can rely on Bopp Busch.

To complement our stamping supplier services, we offer comprehensive welding services, including spot, resistance/projection, mig and tig welding. When we ship your parts, they are ready-to-assemble when they arrive.

Our electro-deposition coating line enables us to finish our customer’s parts in-house using high quality paint supplied by PPG. This state-of-the-art, high-volume system applies a uniformly thick, corrosion-resistant e-coat paint for maximum protection.

If you need parts to arrive ready-to-assemble, we have the capability to pre-assemble parts, including master patches and clips.

We have functioned as a stamping partner supplier for nearly 75 years, we have the experience and knowledge to design your project to meet exact specifications. Our in-house engineering capabilities can aid in the manufacturability of your parts for improved cost efficiency.

Metal stamping relies entirely on careful precision and comprehensive quality control to manufacture components for industries across the globe. This work takes...

The face of metal stamping, as with many other industries across the world, has changed significantly in recent decades due to technological...

The automotive industry is one of the largest utilizers of metal stamped parts, and manufacturers rely on both precision and quality when...

Precision metal stamping is more than simply producing stamped metal components - it encompasses a wide variety of services and processes that...