The tool and die industry is constantly evolving and progressing to adapt to the changing needs of the other industries that it services: automotive, aerospace, customer electronics, etc. As we enter the new year, here are a few up-and-coming trends in the tool and die industry:

Automation

Technology has been steadily advancing for years, and automation has been becoming more and more commonplace within manufacturing companies. From creating product molds to assembly line design, automating is increasing productivity and limiting human error for many tool and die manufacturers. In the coming years, it’s expected that automation will only grow in popularity as new processes are developed to streamline manufacturing across numerous industries.

3D Printing

3D printing is another trend that has grown in popularity over the years, particularly in the manufacturing industry. This form of printing allows exact designs and precise specifications to be replicated at a quicker pace, a lower price, and an increased accuracy. Metal 3D printed parts are becoming more mainstream as a cost-effective measure by major manufacturing companies, and this practice will likely trend upward in the coming years.

Workforce Changes

According to the Manufacturing Institute, nearly 25% of the manufacturing workforce is 55 or older and are quickly retiring out without a comparable wave of new laborers entering the workforce. The ensuing labor shortage, worsened by the “Great Resignation” following the COVID-19 pandemic, has meant that there is an ever-increasing demand for highly skilled tool and die makers. In the coming years, it’s estimated that companies will increase their automated roles, but also pay higher wages and offer more flexible hours to those with the qualifications and certifications necessary to do this important work, making this both a positive and negative trend within the tool and die industry.

Automotive and Aerospace Advancements

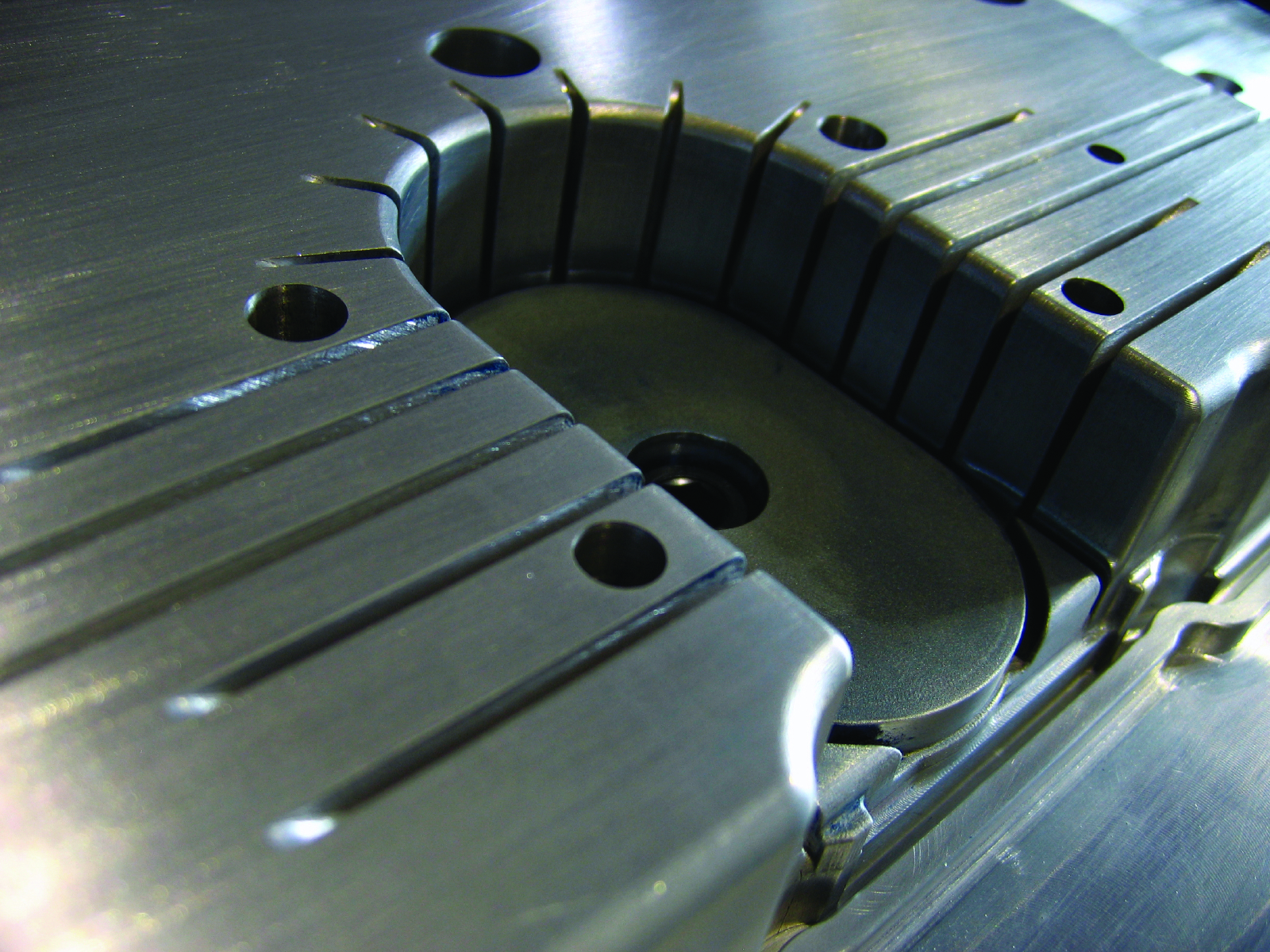

The automotive and aerospace industries have been longtime consumers of metal stamped parts, and thus advancements in those fields open an increased demand within the tool and die industry. The demand for lighter materials, more enhanced safety precautions, and more environmentally friendly products has provided a challenge. However, it also presents an opportunity, for the tool and die industry to adapt and progress. In coming years, it’s expected that the industry will become more specialized to meet the needs of these consumers with advancing specifications and needs.

For 75 years, Bopp Busch has continued to adapt industry practices to deliver a high-quality project efficiently. In addition to our core stamping services, we also offer toolmaking, welding, e-coat paint, general assembly, and design services. To learn more about Bopp Busch and our capabilities, contact us today.