While metal stamping is a broad and versatile industry, it involves carefully precise work with complex equipment. Naturally, challenges often unfold which trusted metal stamping professionals must be able to overcome quickly and efficiently.

Many challenges occur as a result of the materials being stamped. Often metal will crack or deform during the stamping process or, even if no visible problems are apparent, the material will be compromised, and the final stamped product will be less durable than desired. Avoiding this problem involves careful material selection to ensure that the proper metal is being utilized for each particular project. This involves the consideration of numerous factors such as what the final stamped product will be used for, which characteristics are most important, and which materials fit within the consumer’s budget.

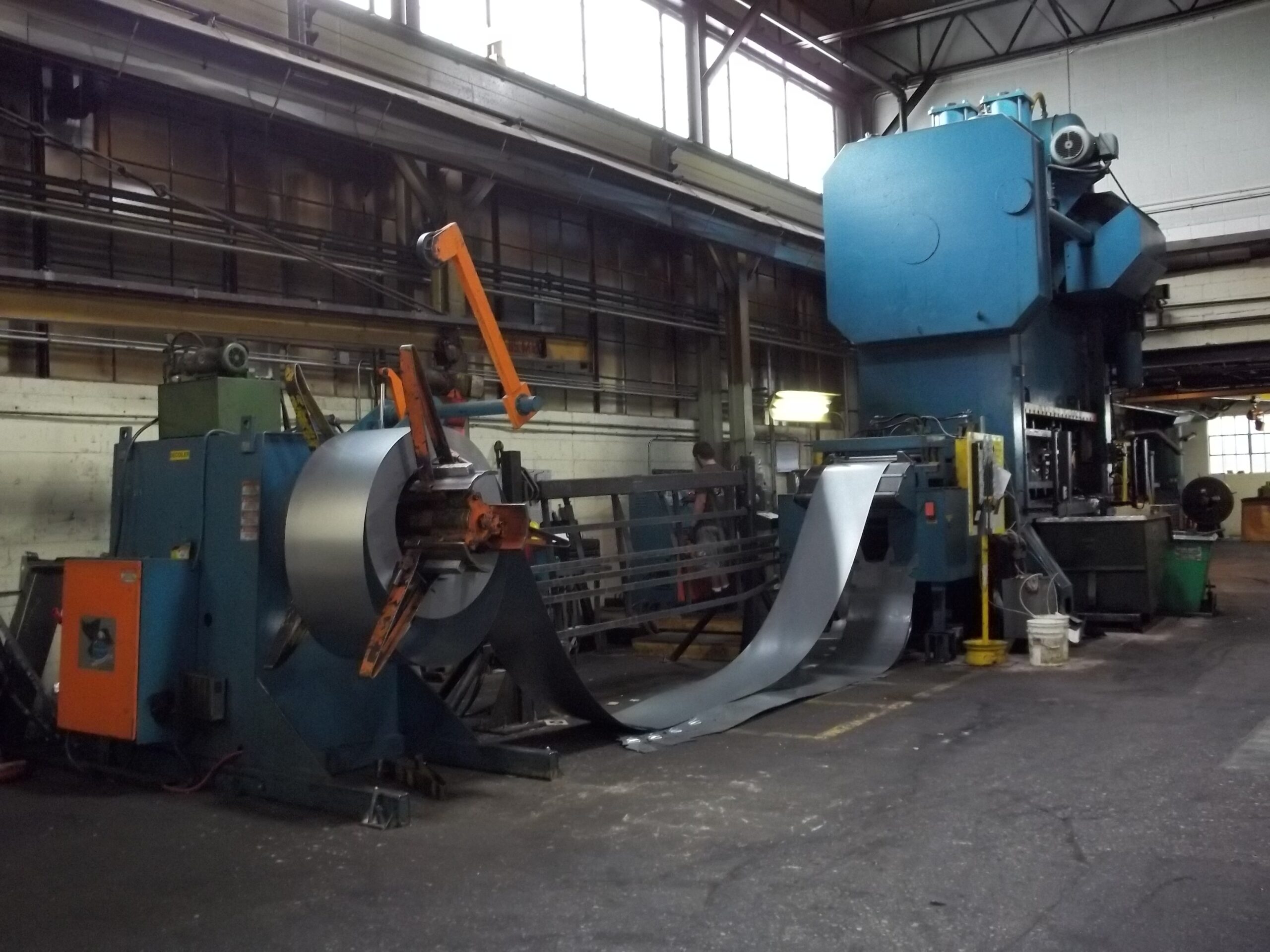

Even with the correct material, challenges can often arise from the equipment and tools being utilized. Without regular maintenance, tools can deteriorate quickly, and can often be overused to the point that they are not as efficient as they should be. Staying on top of tool maintenance, including thoroughly checking equipment prior to beginning a new stamping project, can go a long way in making sure everything is functioning properly.

During the stamping process itself, challenges occur if tools are not designed or programmed properly. For example, if the geometry is even slightly off, holes can be punched unevenly, or the material can crack due to uneven heating or rolling. Utilizing precise pre-stamping processes and quality control checks can provide peace of mind that tools are properly engineered for each unique project, and that the settings being used are appropriate for the material and process that they’re being used for.

As with any manufacturing project, metal stamping involves many operational parts working in tandem to create customized and effective final products. Choosing a qualified metal stamping supplier ensures that any challenges are ready to be faced head-on to ensure client satisfaction.

For 75 years, Bopp Busch has learned to deal with the challenges of our stamping services and have rigid quality control processes in place to serve to our customers. To be a better partner supplier, we have added support services such as e-coat paint, toolmaking, welding, general assembly, and design services. To learn more about Bopp Busch and our capabilities, contact us today.