Metal stamping is a critical component of numerous projects across a versatile range of industries and is responsible for meeting production volumes and creating complex metal components. However, as necessary and innovative as metal stamping is, high-quality products also come with a price tag. Here are a few critical cost factors to consider while budgeting for your unique metal stamping project:

Materials

The raw material utilized for metal stamping projects can vary greatly in price, and it’s important to have a comprehensive understanding of the scope of your project to effectively budget for the type of material needed. For example, simple metal designs like latches or brackets might be able to utilize more budget-friendly materials, while designs for more complex projects such as vehicles or aircrafts require sturdier, more resistant materials with a heftier price tag. It’s important to remember that your budget must be realistic to ensure you can afford the materials needed to withstand the respective conditions and specifications of your unique project.

Design

It goes without saying that more complex or intricate designs will be more expensive than simpler, more standardized designs. For example, smaller mass-produced metal components are fairly affordable, while innovative, custom-made designs may involve more planning, prototyping, and engineering. Collaborating with trusted designers and manufacturers can help ensure that your budget reflects the level of labor and manufacturing that must go into your project.

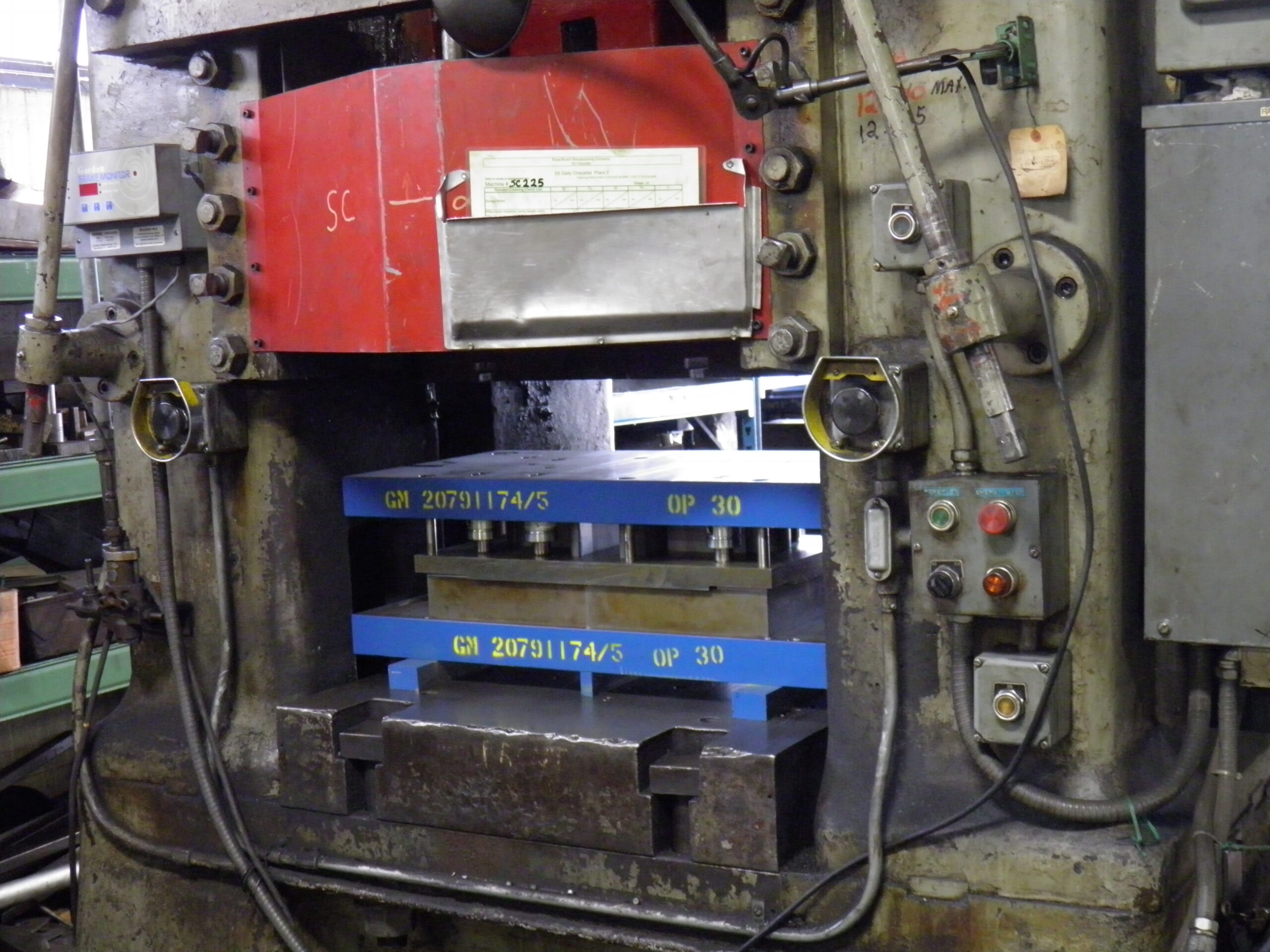

Equipment

Different types of dies and molds come with varying costs related to how precise or intricate the metal stamped design must be. Budgeting for your metal stamping project must include a comprehensive understanding of what type of tooling will be necessary. However, while tooling and equipment costs may seem substantial up front, they often balance out when considering the projected production volume. It’s important to consider batch size optimization, or rather, how much product will be produced overall in comparison to the price of tooling.

Timeline

Considering the timeline of your metal stamping project is crucial when creating a projected budget, as production schedules can have a significant impact on overhead costs. Expedited shipping and quick turnarounds may be inevitable in some circumstances, but it’s most beneficial to provide plenty of lead time to your metal stamping provider to minimize these costs.

In the metal stamping industry, quality comes at a price. Receiving reliable, durable, and safe metal stamped components involves budgeting proactively, and realistically, to ensure that quality is not compromised for affordability. Planning your project budget well in advance utilizing these cost considerations ensures that you can collaborate with your metal stamping provider more effectively, thus providing the opportunity to use cost-saving strategies along every step of your metal stamping project.

At Bopp Busch, providing cost effective serices is paramount. We utilize our diverse in-house services to deliver a high-quality project efficiently. In addition to our core stamping services, we also offer toolmaking, welding, e-coat paint, general assembly, and design services. To learn more about Bopp Busch and our capabilities, contact us today.