What is Metal Stamping?

This article will touch on several topics of the metal stamping process. The cold forming process of shaping a metal sheet into various shapes using a die and stamping press is known as metal stamping. A portion of a metal sheets subjected to a stamping press, which has a die installed within to give the metal the required shape.

Comprehending Metal Stamping

Pressing or compound metal stamping is a high speed and low cost manufacturing process capable of generating identical metal components in large production volumes. It is viable for both long and short production runs. This process of metal stamping may be comprised of a single or an amalgamation of several techniques as follows:

- Blanking

- Coining

- Punching

- Flanging

- Embossing

- Bending

There are many stamping operations such as progressive die stamping, transfer die stamping, fine blanking, and four slide stamping. Metal stamping uses three common types of stamping press, the mechanical servo, mechanical, and hydraulic.

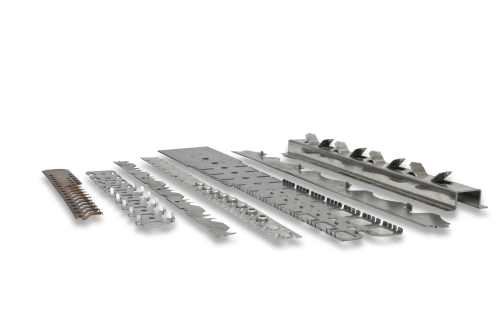

There are several stamping dies used by Tier 2 suppliers in the process of metal stamping. These dies are divided into two classifications; single-station and multiple-station dies. The former is made up of combination dies, and compound dies, whereas multiple-station dies include transfer dies and combination dies. The material chosen for stamping depends on its characteristics and the requirements of the finished product.

The Benefits of Stamping

Metal stamping is more beneficial over other fabrication processes for the following reasons:

- Lower die costs

- Lower secondary costs

- Increased automation level

The pros of metal stamping far outweigh its few cons, making metal stamping the most popular form of fabrication in use today.

Bopp Busch has been stamping parts since 1948. We are committed to meeting the demands of our customers with quality and on-time services. To learn more about Bopp Busch and our capabilities, contact us today.

I liked how you mentioned that metal stamping is more beneficial over other fabrication processes because of lower secondary costs. I’ve been wanting to find good ways to fabricate something I’ve been working on. Maybe I should reach out to a metal stamping professional near me.